Part One: Textured black for MDF cabinets

With any DIY speaker project, you’ll hit that important point in the process where you have to make a decision about the finish. Some know what to do and how to do it while their cabinets are just plans on a page or pre-cut panels in a kit whereas others may’ve left their built speakers sporting a raw MDF style for several weeks. The latter is not uncommon, especially if you’re new to DIY audio. Many of us put this step off thinking it’s going to be beyond our abilities to produce a professional looking finish. In this article, and the next, we’ll introduce you to two simple yet exceptional looking finishing methods you’ll be proud to display. Don’t put those finishing touches off any longer!

In part one we show you how to achieve a textured black finish using DuraTex which can be applied direct to raw MDF without priming. DuraTex is very popular in pro audio where it is often applied in a very heavy texture. Here we’ll show you how it can also be effectively used in home audio where a finer texture works well. In the accompanying photos, you’ll notice an LSK M4 MkII mini monitor kit is being used as an example.

First, we’ve listed below the tools you’ll require to complete the process. Notice that some tools are optional while the necessary tools are easily accessible to everyone.

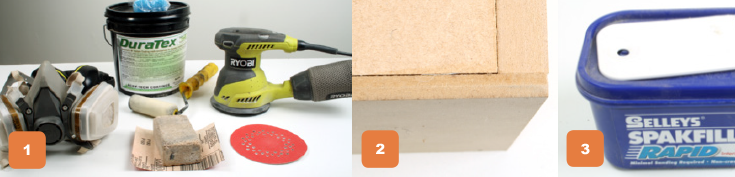

Tools and supplies (image 1):

- DuraTex textured paint

- 100mm roller

- MDF cut-off (or similar) to rest cabinet on

- spackle type filler and application tool

- sandpaper (120 grit)

- orbital sander with 120 grit paper (optional)

- ear muffs and dust mask (if using sander)

- damp rag

Step 1: sanding and filling

MDF has a waxy surface coating which should be sanded down prior to painting to ensure adequate adhesion of the textured paint. In addition, during the construction process, especially where clamps have not been used, the panels might not line up perfectly. It’s in this first step that this should be resolved by sanding and/or filling with a spackle filler.

As you can see in the photo, gaps in the joins can also be present due to inadequate pressure during the construction process (image 2). These should also be filled using a spackle filler. Please note that many fillers are not suitable for use with DuraTex. Be sure to use a spackle type filler (such as in image 3). Make sure you also observe the drying times on the filler you are using before proceeding. If you are sanding uneven edges, don’t be deterred if you are not in possession of an orbital sander such as the one used in the photo because a sanding block is also effective (image 4).

On completion of this step, you should now have removed the waxy surface coating from the MDF. Also, any gaps should have now been filled and uneven edges either filled or sanded flat.

Step 2: round overs (optional)

This next step is optional but we’ve included it because round edges, particularly the corners on the front of your cabinet, improve the frequency response. Irregularities and interferences occur when you have sharp edges on your speaker cabinets. In speaking building, this is known as diffraction.

In addition, rounding the edges of your cabinet will conceal butt joins that have a tendency to emerge as an unsightly crack in paint finishes. These are extremely difficult to avoid in any paint finish but this step helps to minimise the risk. However, to perform this task you will need a router with round over bits and, ideally, a router table.

In the pictured example, we used a 13mm round over bit on the edges between top/bottom and sides and a 6mm round over bit on front and back edges. If you have a router table, this is the best method. The box is moved cross the bit and hands are kept well away. If you only have a router, the box must be fixed in place and the router moves over the edges. This is quite difficult and requires some care to avoid slips.

This option should not be attempted by those who are not experienced in using power tools. It must also be noted that the round overs require sanding, as the result will never be perfect. Ensure the sandpaper conforms to the shape of the curve (images 4 and 5).

If you are completing this optional step, you will also need to do another round of filling (image 7). The rounding process will take off a lot of the original filler and will sometimes expose voids where the filler wasn’t pushed down far enough in the first step.

Don’t be disheartened if you have to skip this step. You will still end up with great looking speaker cabinets with exceptional quality sound (well, we should add that we can really only guarantee the sound quality if you’ve purchased quality, compatible components or a kit from LSK of course)!

Step 3: applying the first coat

DuraTex can be applied with many types of rollers but we recommend a 100mm roller to keep things simple. A small roller means that no tray is required as it can be dipped right into the paint tin, making clean up a whole lot easier. Here we’ve used a disposable foam roller (image 8) which provides a fine texture. Dedicated texture rollers can also be used for a heavier texture.

The best way to proceed is to elevate the box with a small MDF off cut or similar item. This means the base requires painting in a later application but it will make the whole process easier overall. Alternatively, you can hang the box so the entire box can be coated in one application but this is a more difficult method.

Be careful in applying the coat to the front baffle (image 8). This coat should be quite thin, otherwise the paint will get into the driver recesses which potentially means the drivers won’t fit. As an example only of thick application, here the back receives a thick coat (image 9). Thicker application can mean less coats are required but this also leads to a heavier texture and is not ideal near recesses, particularly on the front baffle.

Step 4: further coats

Unlike other paints, further coats of DuraTex can be applied before the paint has dried completely. However, when it comes to placing a recently painted side of your speaker cabinet onto the block under the box, it’s a good idea to wait around an hour. DuraTex dries fast, but takes much longer to fully harden.

If the first coat is sufficiently thick, it may not be necessary to use more than one coat. However, it’s best to use two or three thin coats. On the front baffle, a single thick coat would likely cause problems as mentioned previously. Also, it will be very hard to achieve an even texture if you try to shorten the process by applying a single thick coat on the sides while doing two or three thin coats on the front.

Hints and tips:

- As we mentioned above, although it dries fast, DuraTex takes much longer to fully harden. If you place one DuraTex box on top of another too soon after application they may stick together.

- Rolling DuraTex is not like rolling wall paint. Wall paint is best applied with a wet edge. With DuraTex, it is often a good idea to go over an area as the paint starts to dry, without adding any paint to the roller.

- We also recommend experimenting with application techniques. There are many variations that can provide a different result.

If this method hasn’t caught your attention, or even if it has, stay tuned for part two!